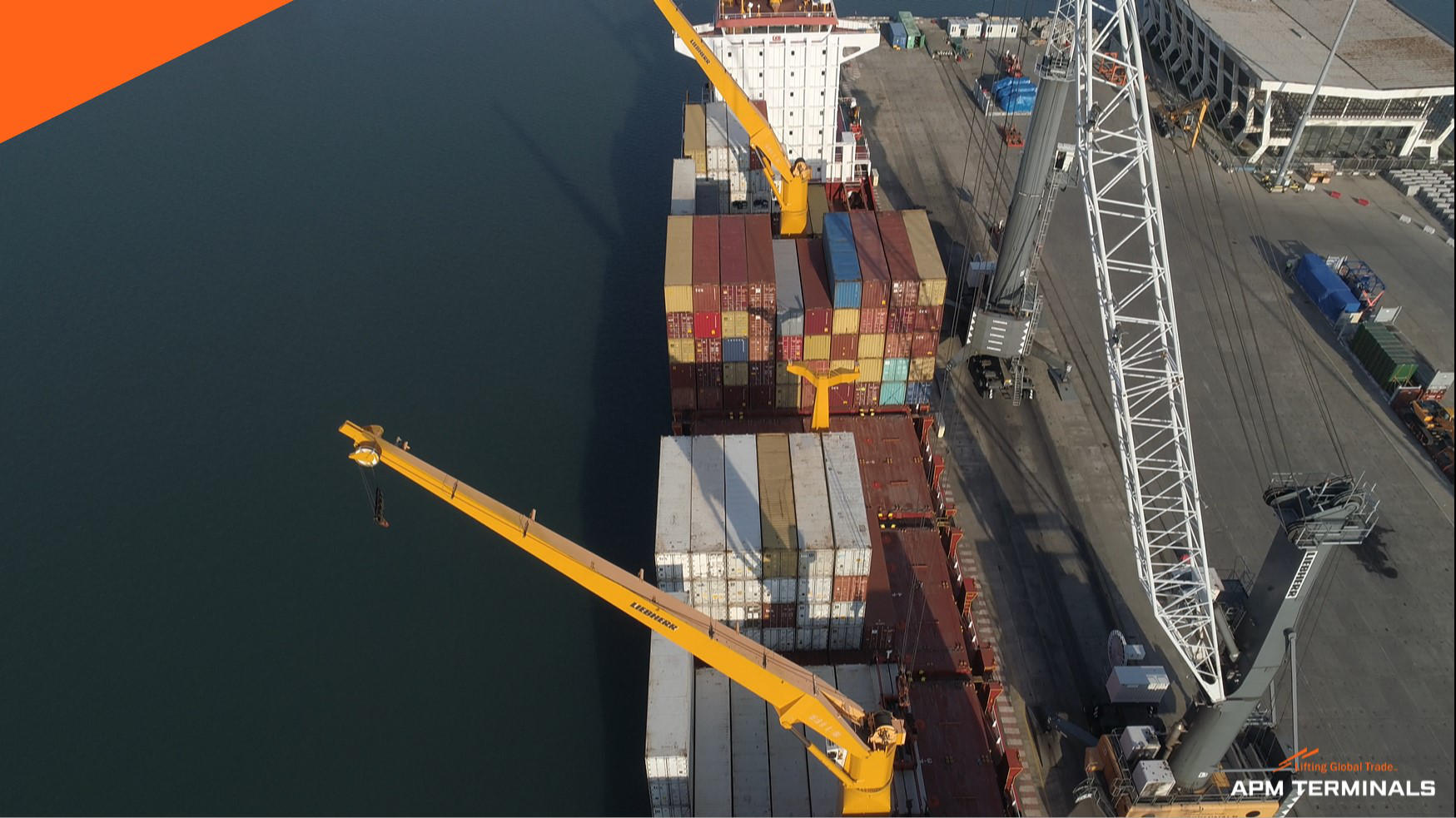

APM Terminals Poti releases information on cargo handling operations

Following on from achieving a shift productivity record in May at APM Terminals Poti, Operations Team continues its devoted work for effective cargo handling and customer experience improvement. This latest achievement relates to the zero operational delays during Milaha vessel handling, APM Terminals Poti told InterPressNews.

Each part of the supply chain, from truck drivers to forwarders, shipping lines, different terminals and ports of discharge, has a huge impact on all customers transporting goods in the country and the region through Poti Sea Port. Therefore, it's crucial that goods, materials, medicines or cargo for business trade are transferred smoothly and end-users receive services and products on-time.

To enhance handling efficiency and decrease delays, an alternative model for cargo handling has been created in the beginning of the year. Model relies on full coordination with all stakeholders in vessel handling process and exchanging information in real-time, which was successfully used during “Milaha” vessel handling - a ship of the relatively new Qatari shipping line.

“Milaha” vessels are sailing through the Black Sea Express Service, which connects Poti to Piraeus, Istanbul-Kumport, and Novorossiysk Ports. As soon as the epidemiological situation has been lightened, the operations team started to work on Milaha Vessel with the new model, despite complex nature of the operations the team reached an exceptional result – 0 delays during Milaha vessel handling. 5 vessels have been tested in terms of the project, showing significantly less delay on all of them and zero holdup on the last one.

Achieving Hitting this success and seeing the excellent results, APM Terminals Poti operations motivated team will continue working with stakeholders with full coordination, one approach to problem-solving and readiness to support each other during cargo handling as long as demurrage elimination is equally important for all parties – customers, who receive cargo on-time and save a significant amount of costs, and for the company as well, in terms of berth and equipment effective utilization.

The full implementation of this project was interrupted by the COVID-19 pandemic but will be processed in a new manner as soon as the working style returns to normal.

”It is often said that a ship is not making money whilst it is not moving, and in fact in certain circumstances the shipping companies pay penalties (demurrage) due to the vessel not keeping to its schedule, adding costs to the whole supply chain which in turn increase costs of the finished goods in shops. It is therefore important that avoidable delays in the logistics chain are kept to a minimum, and it takes close coordination and cooperation from all entities involved in the supply chain to do so. Achieving this result is testament to the efforts of all involved, and further demonstrates the efficiency of Poti Sea Port community continuing and enhancing international trade in Georgia and the wider region,“ – said Matthew Rantanen, COO of APM Terminals Poti.